Are you just starting to digitize, or already running predictive systems in your operations?

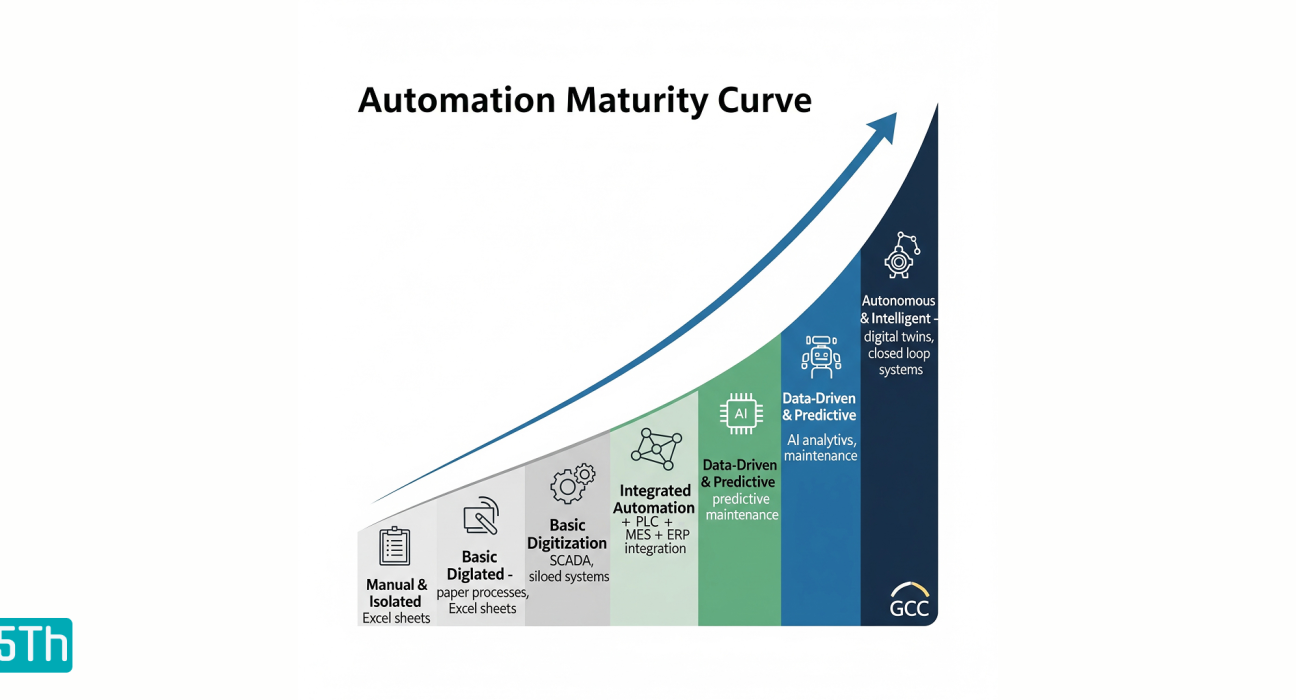

Understanding where your company sits on the Automation Maturity Curve can help you plan better investments, avoid inefficiencies, and benchmark against regional peers.

In this article, we’ll break down the 5 stages of automation maturity, show what each stage looks like in real-world companies, and help you self-assess your current level.

✅ Stage 1: Manual & Isolated

- Systems: Paper-based, Excel spreadsheets, offline equipment

- Characteristics: No real-time visibility, high error rate, reactive maintenance

- Common in: Legacy factories, small plants, logistics warehouses

🔧 Example: A warehouse in Oman using basic barcode scanners and Excel sheets to manage inventory, without any integrated system.

✅ Stage 2: Basic Digitization

- Systems: Some SCADA/HMI, siloed automation (no central control)

- Characteristics: Manual reporting, limited analytics, some human-machine interface

- Focus: Replacing paper with screens, not optimizing processes yet

💡 Example: A UAE facility with SCADA for machine control, but with no integration into ERP or central dashboards.

✅ Stage 3: Integrated Automation

- Systems: PLCs, MES, ERP integration, centralized data flows

- Characteristics: Data sharing across departments, event-based alarms, real-time monitoring

- Focus: Process optimization, less human error, better uptime

🔍 Example: A food processing plant in Saudi Arabia linking production line sensors to dashboards that alert supervisors before failures occur.

✅ Stage 4: Data-Driven & Predictive

- Systems: Predictive maintenance, AI-based analytics, edge computing

- Characteristics: Early AI deployment, forecasting failures, energy optimization

- Focus: Prevent problems instead of fixing them

📈 Example: An oil refinery in Kuwait using AI to analyze sensor data and forecast pump failures days in advance.

✅ Stage 5: Autonomous & Intelligent

- Systems: Full cyber-physical systems, digital twins, closed-loop automation

- Characteristics: Self-adjusting systems, minimal human input, adaptive controls

- Focus: Efficiency at scale, autonomous decisions based on real-time conditions

🤖 Example: Rare in GCC today, but projects like NEOM aim to reach this level using AI, robotics, and autonomous logistics.

📌 How to Assess Your Company’s Stage

You can create a simple internal checklist or assessment based on:

- Process visibility (manual vs. real-time dashboards)

- System integration (siloed vs. centralized)

- Decision-making (human-led vs. data/AI-driven)

- Maintenance model (reactive vs. predictive)

- Workforce enablement (operators vs. digital workers)

💡 Tip: Many companies think they’re at Stage 4 when they’re really at Stage 2 with basic dashboards and no predictive functionality.

🚀 How to Move Up the Curve

Here are the key levers to advance your maturity level:

- Start with a baseline audit – understand current systems and pain points.

- Integrate your data flows – connect SCADA, ERP, and MES layers.

- Train your people – adoption only works if operators are onboard.

- Invest in predictive tech – sensors, AI models, edge computing.

- Measure ROI – show leadership real savings to secure more budget.

🧭 Why It Matters in the GCC

- Governments are pushing Vision 2030, Industry 4.0, and digital transformation agendas.

- Companies that stay in Stage 1 or 2 will fall behind in efficiency, funding access, and talent retention.

- Smart industry players are using this maturity model as a strategic roadmap.