Quality control has always been a bottleneck in high-speed production environments. Human inspectors get tired, lighting conditions change, and defects slip through. That’s where machine vision steps in — combining cameras, sensors, and intelligent algorithms to spot flaws in real time with incredible precision.

📸 What Is Machine Vision?

Machine vision refers to the use of cameras, image processing software, and AI to “see” and interpret the visual aspects of a product, component, or environment.

Unlike human vision, machine vision:

- Is consistent (24/7 operation)

- Works at high speed (ms-level image processing)

- Can detect subtle anomalies that humans miss

It’s used across:

- Assembly lines

- Packaging systems

- Surface inspection

- Dimensional accuracy checks

- Barcode/QR code reading

🏭 Use Cases in Quality Control

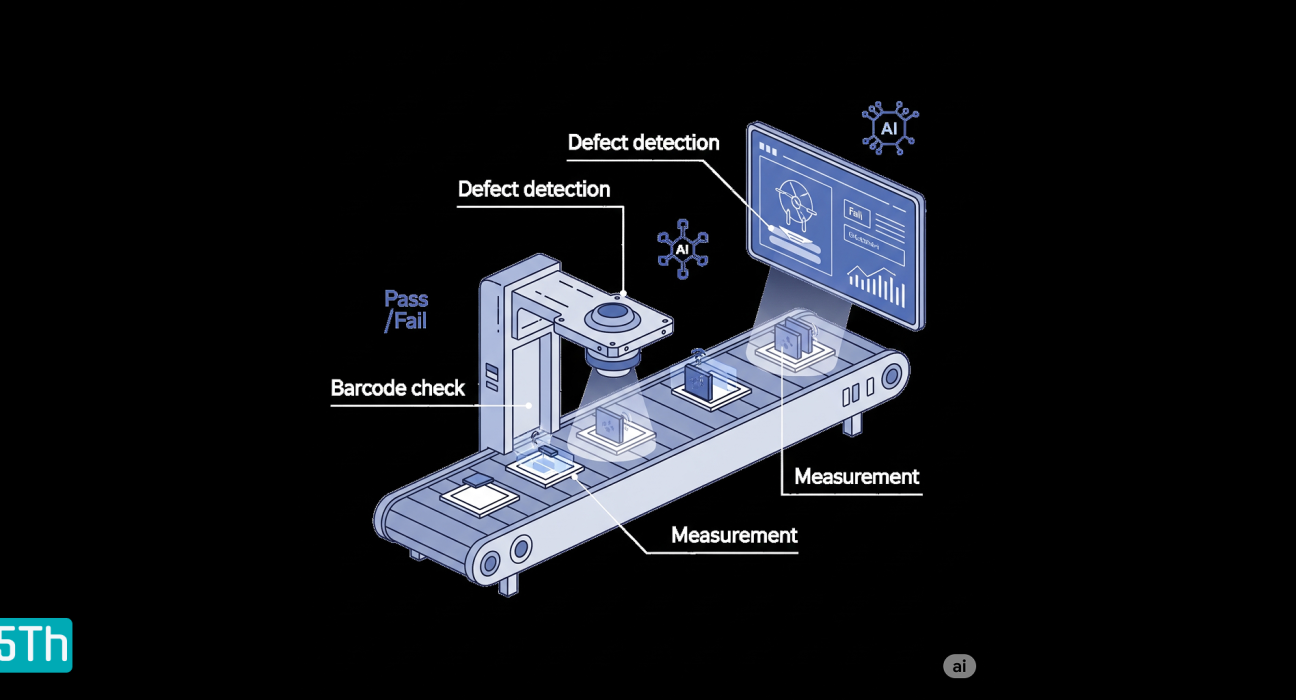

🔹 1. Defect Detection in Manufacturing

Surface scratches, cracks, discoloration, missing parts — all can be automatically detected using machine vision, reducing the need for manual inspection.

Example: An aluminum extrusion plant in UAE uses high-speed line scan cameras to detect micro-defects in real time.

🔹 2. Label and Barcode Verification

Ensures labels are present, correctly printed, and properly aligned — especially critical in pharma, food & beverage, and retail.

Example: A packaging facility in KSA uses Cognex vision sensors to check pharmaceutical labels for accuracy.

🔹 3. Dimensional Measurement

Machine vision systems measure lengths, widths, angles, and even complex contours to ensure parts meet tight tolerances.

🔹 4. Assembly Verification

Checks whether all parts are present and correctly assembled — often integrated with robotic systems.

🔹 5. Color & Pattern Matching

Used in textiles, printing, and automotive industries where color consistency is crucial.

🤖 AI + Machine Vision = Smart QC

Modern machine vision systems are increasingly AI-powered:

- Convolutional Neural Networks (CNNs) classify defects with high accuracy

- Anomaly detection models identify “abnormal” but undefined flaws

- Edge AI devices process data locally with minimal latency

These tools not only detect issues but learn from patterns, making them ideal for continuous improvement in automated QC loops.

📉 Benefits of Machine Vision in QC

| Benefit | Impact |

|---|---|

| Consistency | Eliminates variability from human error |

| Speed | Real-time inspection without slowing production |

| Cost Saving | Reduces rework, scrap, and recall risk |

| Compliance | Meets ISO and industry-specific QC standards |

| Traceability | Image logs for every inspected unit |

🌍 Adoption in the GCC

In the GCC, machine vision adoption is growing, particularly in:

- F&B (automated inspection of packaged goods)

- Pharma (anti-counterfeiting, serialization)

- Oil & Gas (pipeline inspection, flare monitoring)

- Automotive (weld inspection, part alignment)

Governments supporting smart industry programs (e.g., Vision 2030, In-Country Value programs) are driving adoption across national and private sector factories.

Pro tip: Look at COMEX Oman or GITEX UAE booths for emerging machine vision integrators and distributors.

⚠️ Challenges & Considerations

- Lighting conditions can affect camera accuracy

- Initial cost for camera systems, lenses, lighting, and software

- Integration complexity with existing PLC/MES/SCADA systems

- AI training data requirements if using custom models

Still, the ROI becomes clear after just a few months in medium to high-speed production lines.

✅ Conclusion

Machine vision is no longer a futuristic concept — it’s a current necessity for any business serious about zero-defect production and automated, scalable quality control.

Whether you’re inspecting engine parts, labels, or food packages, machine vision delivers measurable improvements in efficiency, reliability, and compliance.